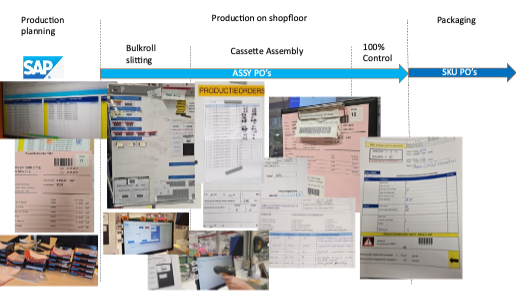

Connecting SAP ERP with machines

Label application maker Dymo wanted to become paperless. Devoteam connected their SAP ERP for production planning with the automated machines of the Dymo plant in Belgium. They asked Devoteam to digitize all information flows on their shop floor. By managing the production orders digitally end-to-end, from planning until delivered goods, Newell brands will be able to respond with much more flexibility to market demand.

The client

Dymo is the number one in Europe for label applications for household use, specifically for offices and industrial settings. It is part of Newell Brands (NASDAQ: NWL), a leading global consumer goods company with a strong portfolio of well-known brands, including Rubbermaid®, Paper Mate®, Dymo®, Parker®, Rotring®, Waterman®.

The Dymo plant in Sint-Niklaas, Belgium is recognized within Newell Brands for its innovation and its track record to realize better Overall Equipment Effectiveness (OEE) and increased productivity year over year. The foundation for this paperless project was already realized through the automation of machine data logging.

The challenge

Dymo was looking to digitize the administration work by its people – starting with the production planning on the shop floor. Here several fulltime-equivalents (FTE) of work were lost in Excel, emails, paperwork, and manually copy-pasting scrap and production quantities into SAP.

Once this project has been rolled out across the whole department, we will be able to respond to market demand in a very flexible way.

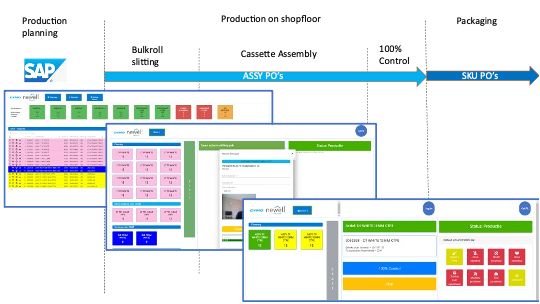

The solution

When Dymo visited the paperless project at Duracell, they saw what Devoteam achieved there: connecting people through digital shop floor portals with SAP ERP, the Warehouse system, the Manufacturing Execution System (MES) and machines.

In 2019, Dymo and Devoteam jointly conducted a content analysis to identify the improvement potential, a roadmap, and implementation trajectory to realize a positive business case with the digitization of key information flows. This exercise convinced Dymo’s headquarters to trust Devoteam with a 2-year digital transformation project. We started the journey in April 2020, in partnership with Microsoft and Ometa.

One year further, we created digital portals for:

- the people of production planning

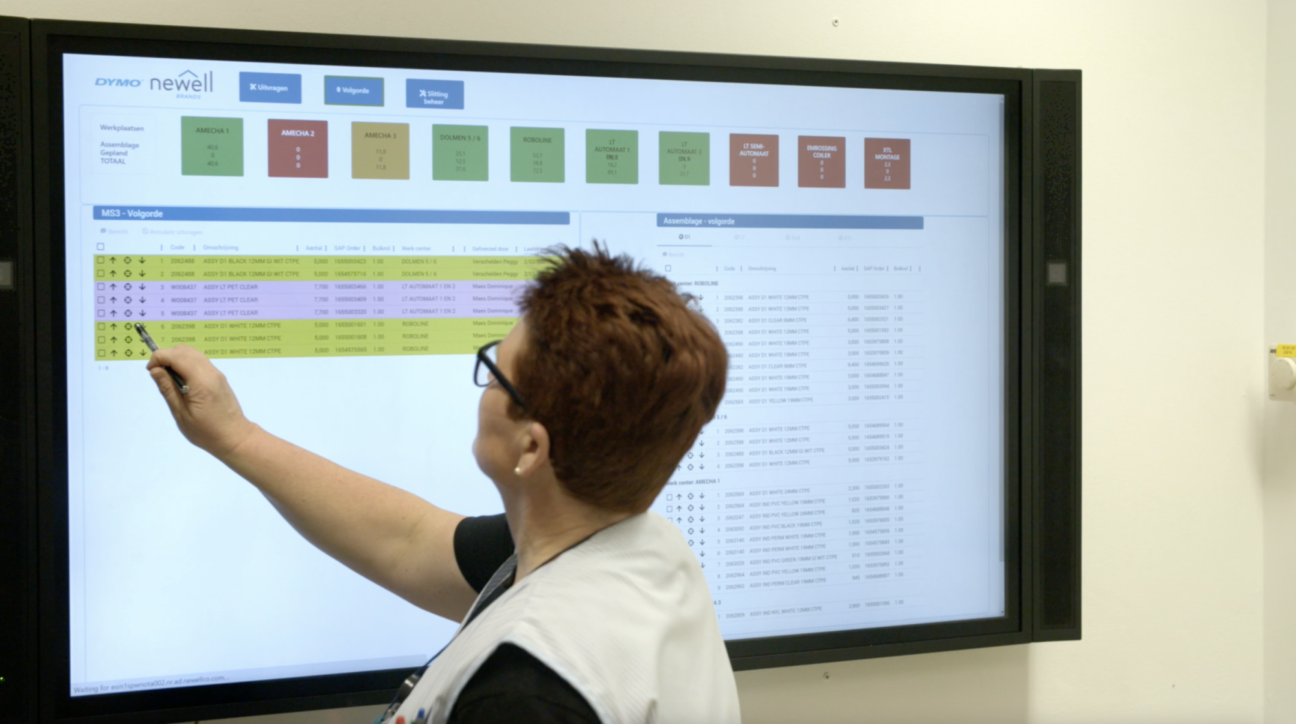

- the shift and team leaders for production follow-up and replanning

- the machine operators and the 100% control tables

- safety and maintenance follow-up

- production management for OEE processing

When you can achieve this – digitizing your entire production process and making a real difference for the people on the job – that’s what it’s all about.

With our solution, we save FTEs of dull administrative work, by killing the need for manual work such as Excel exports, emails and paperwork. By getting the data automatically from its sources, we improved the data quality of OEE, productivity, quality, safety and maintenance. On top of that we eliminate human errors.

Our team can proudly say that we made a real difference for the people on the shop floor. Here’s an example. Previously the administration at the end of a bulk roll slitting job took the operator and team leader on average 15 minutes of administration work. Today’s portals reduced that work to 1 to 2 minutes. In the end, Dymo’s people gain time to work more proactively on further improvements.

After the paperless project, Devoteam continues to support Dymo by:

- Extending the digitization – from production assembly to packaging, operator training and other production lines

- Connecting production with supply chain – from an Industry 4.0 vertical to horizontal integration

- Going from a speed to smart factory – leveraging today’s and future data-driven intelligence capabilities